With the transformation of production methods in the manufacturing industry, mobile robots, as intelligent logistics devices, have begun to enter the public's vision. Mobile robots can not only meet the needs of logistics handling, but also flexibly integrate different functional modules according to the process flow of various industries, making production more intelligent and flexible. By combining with Muteng Robotics RCS and iWMS, and integrating with Warehouse Management System (WMS), Manufacturing Execution System (MES) and other information systems, intelligent warehouse management can be achieved.

As a leading provider of mobile robot products and services, Muteng Robotics, based on its profound technological and practical accumulation, has insight into the changing needs of the industry, and provides professional, intelligent, flexible and practical industry solutions to the entire industry, intelligently leading the transformation of internal logistics.

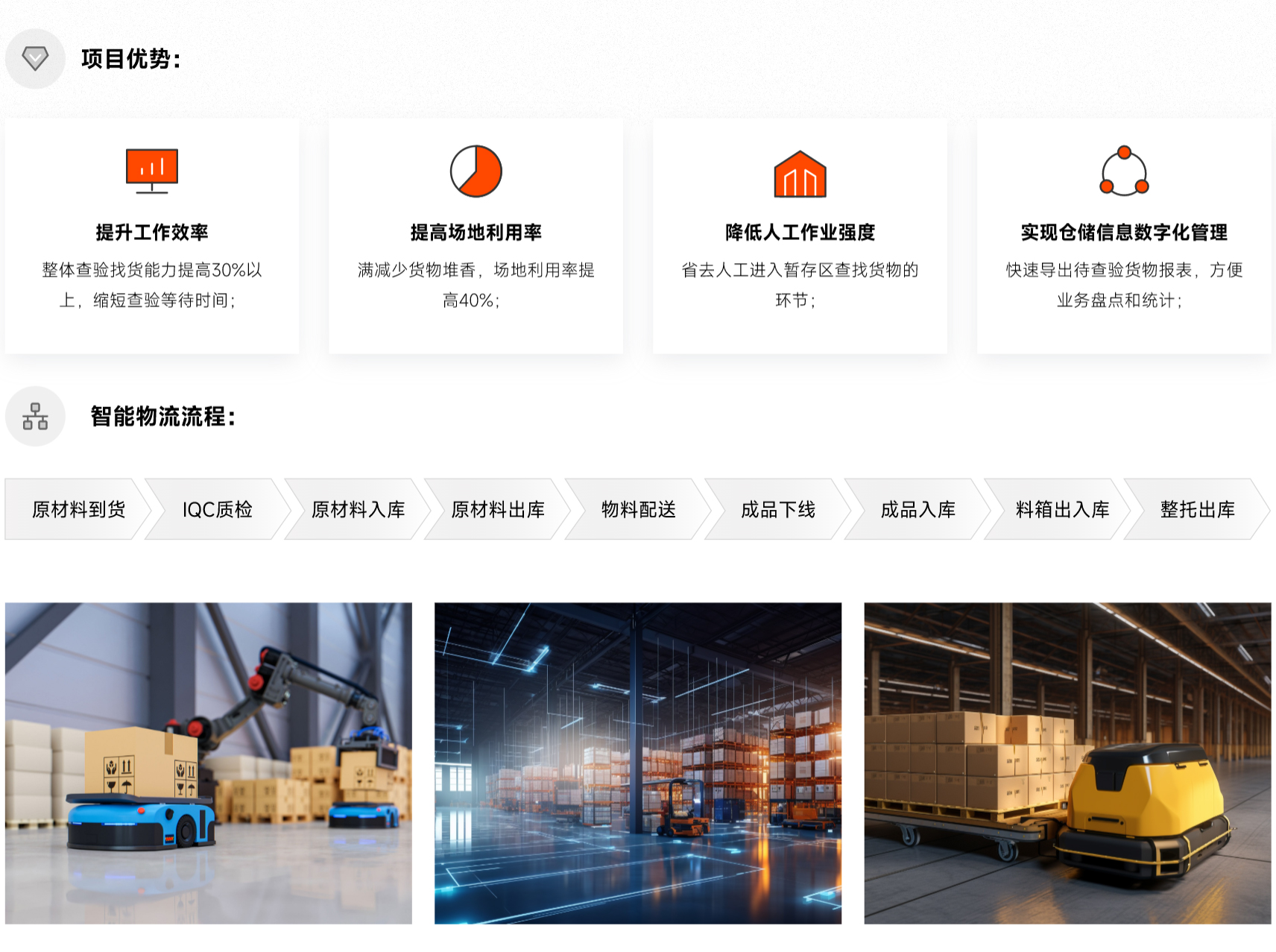

Project advantages:

Improve work efficiency: Increase overall inspection and finding ability by more than 30%, shorten inspection waiting time;

Improve venue utilization: reduce the stacking of goods and incense, and increase venue utilization by 40%;

Reduce manual workload: eliminate the need for manual entry into temporary storage areas to search for goods;

Realize digital management of warehouse information: Quickly export reports of goods to be inspected, facilitating business inventory and statistics.

Intelligent logistics process: raw material arrival - IQC quality inspection - raw material warehousing - raw material outbound - material distribution - finished product offline - finished product inbound - material box inbound - whole pallet outbound

CN

CN EN

EN